فومن، گیلان – سرپرست اداره حفاظت محیط زیست شهرستان فومن از رفع تصرف بیش از هزار متر مربع از زمینهای ملی در من...

جولای 5, 2025

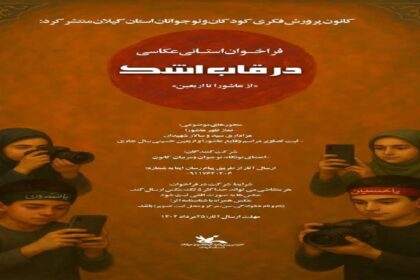

گیلان – کانون پرورش فکری کودکان و نوجوانان گیلان از آغاز به کار مسابقه عکاسی “در قاب اشک” خبر داد. هدف از ...

جولای 5, 2025

رشت، گیلان – رئیس مرکز مدیریت راههای اداره کل راهداری و حمل و نقل جادهای استان گیلان از ثبت آمار نگرانکنن...

جولای 5, 2025